Profile projectors and optical machines are essential tools in modern machine shops. Thanks to their precision and versatility, these devices have become indispensable for ensuring quality and efficiency in production processes. In this in-depth look, we will explore in detail what profile projectors and optical machines are, how they work, their advantages and practical applications in industry.

Introduction to profile projectors and optical machines

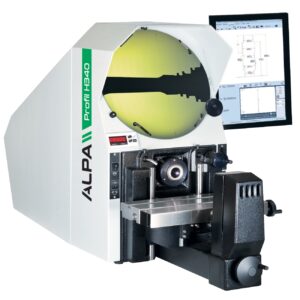

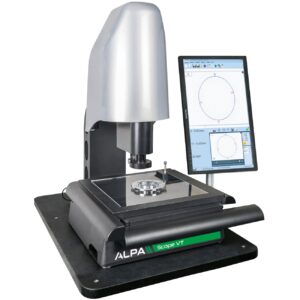

Profile projectors and optical machines are optical measuring instruments used for inspecting and verifying the dimensions of mechanical components. These devices allow an enlarged image of an object to be projected onto a screen, enabling operators to examine the geometric and dimensional characteristics of the part under examination in detail. The ability to magnify the image allows even the smallest imperfections to be detected, thus ensuring accurate quality control.

Operation and technical characteristics

The operation of profile projectors is based on an optical system that projects the image of an object onto a screen. The object is placed on a measuring table and illuminated by a light source. The image is then enlarged through a lens system and projected onto a screen, where it can be precisely measured. Optical machines, on the other hand, use advanced technologies such as laser scanning or optical tomography to obtain detailed three-dimensional measurements.

The technical characteristics of these instruments vary depending on the model and specific application requirements. However, some common elements include magnification capacity, optical resolution, measurement accuracy and ease of use. Profile projectors can offer variable magnifications, usually between 10x and 100x, while optical machines can achieve extremely high levels of precision, often in the order of microns.

Practical applications in machine shops

In machine shops, profile projectors and optical machines are used in a wide range of production processes. They are particularly useful for quality control of complex components, where accuracy is crucial. For example, they can be used to check the conformity of gears, shafts, bearings and other critical components. They are also used in the production of moulds and tools, where dimensional accuracy is essential to ensure the functionality of the final product.

Advantages of using profile projectors and optical machines

The adoption of profile projectors and optical machines offers numerous advantages to machine shops. Firstly, they significantly improve measurement accuracy, reducing the risk of errors and defects in final products. This translates into higher quality and reliability of the manufactured components, resulting in increased customer satisfaction.

In addition, these tools save time and resources. The ability to perform quick and accurate measurements reduces the need for laborious and time-consuming manual inspections. This translates into greater operational efficiency and reduced production costs.

Frequently asked questions about profile projectors and optical machines

1. What is the difference between a profile projector and an optical machine?

- Profile projectors use an optical system to project an enlarged image of an object onto a screen, while optical machines can use advanced technologies such as laser scanning to obtain three-dimensional measurements.

2. What are the main areas of application?

- These instruments are widely used in machine shops, the automotive and aerospace industries and in tool and mould making.

3. What are the advantages of using these instruments?

- They offer measurement accuracy, improve product quality, reduce inspection time and operating costs.

4. How do I choose the right profile projector or optical machine?

- The choice depends on the specific application needs, such as the level of accuracy required, the size of the components to be measured and the available budget.

5. Is specific training required to use these tools?

- Although many models are designed to be intuitive, proper training is recommended to maximise the effectiveness and accuracy of measurements.

Conclusions

Profile projectors and optical machines are an invaluable resource for machine shops striving for manufacturing excellence. Their ability to provide accurate and reliable measurements helps to improve product quality and optimise production processes. Investing in these tools means equipping yourself with advanced technology that can make the difference in an increasingly competitive market. As measurement technology continues to evolve, it is essential to stay up-to-date and adopt innovative solutions to maintain a competitive edge in the industry.

Showing 1–24 of 36 results